Seeing Is Believing.-----An Order From Honduras

Seeing Is Believing.-----An Order From Honduras

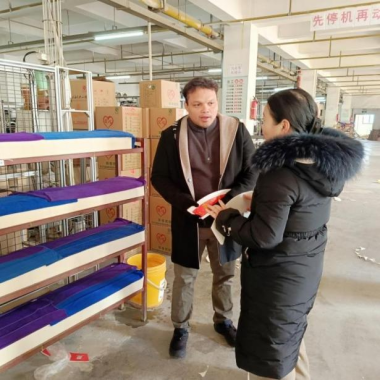

As the sun rose in the east and the warm sunshine flooded every land, I, Tommy, a sales representative for an Export Machinery Company, took my foreign client, Mr. Rodriguez from Honduras, on a journey to China. Our goal is to visit Xin Oasis factory located in the central city of China, which is a professional manufacturer of paper cup raw materials and paper cup fan. Mr.Rodriguez runs a paper cup molding factory in his country and wants to find stable suppliers of raw materials and paper cup fans in China. We were greeted by Sharon, the factory manager, who has many years of rich industry experience and deals with customers from all over the world. She has delivered the factory's high-quality and exquisite products to foreign countries across the ocean. I hope that her introduction today can benefit me and Mr. Rodriguez a lot!

First stop: modern factory environment

As soon as we step into the door of Xin Oasis, we feel the modern atmosphere of this factory. Spacious and bright workshop, sufficient industrial materials, as well as a clean and orderly environment, all kinds of advanced production equipment in the workshop neatly arranged, the workers skilled and focused operation, showing a high level of professionalism. All show the high level of China's manufacturing industry. Mr Rodriguez was impressed. He raved about the cleanliness and modernity of the factory.

The second stop: efficient production equipment

With the guidance of Sharon,we toured the production facilities.

First she introduced us to the film machine:

The original film coating machine, also known as extrusion composite machine, has a high degree of automation, easy operation, high production speed, uniform coating thickness, high bonding fastness, rolling flat, environmental protection and no pollution, can effectively save labor and raw material costs.

Followed by the bottom paper cutting machine and the cutting machine:

They have high production efficiency and can be cut quickly in a short time. This high efficiency production capacity is the pursuit of paper processing manufacturers, because time determines the production cost and order delivery time and other important factors. It can flatly cut the paper roll, avoid deformation or breakage of the paper, and improve the quality control.

Next came flexographic presses:

This is a kind of flexographic printing equipment using flexographic printing, the combination of flexographic and hard plate structure, can improve the printing accuracy and efficiency through electronic control, compact structure, printing speed, reusable, with seven color printing function, high quality of finished products.

Finally, automatic packaging machines and forming machines:

Automated packaging processes can significantly improve production efficiency and reduce human contact while ensuring food hygiene and safety. Although the initial purchase cost of the paper cup packaging machine may be higher, the long-term demand can reduce labor costs and improve efficiency.

In addition, the factory's staff training system is also very perfect. Employees can not only learn professional skills here, but also continuously improve their quality, which provides a solid talent guarantee for the sustainable development of the factory. According to Sharon, many of the old masters in the factory have worked for more than 10 years, and are very professional in the process of raw materials and manufacturing details. This is enough to reflect the humanistic care spirit of the factory for employees in all aspects, so that employees continue to follow the development of the factory and love the industry.

The third stop: General manager talks

The head of the factory, General Manager Fan, attached great importance to Mr.Rodriguez's arrival, introduced the development history of our factory in detail, and had an in-depth understanding of Mr.Rodriguez's product demand, annual purchase volume, purchase cycle and delivery time. In the past, he said, they had relied on foreign suppliers, and erratic product quality and unpunctual delivery times were often a headache. After this field visit, he was very satisfied with the professional level and comprehensive strength of Xin Oasis factory. He said that he is very happy to see such a strong and competitive Chinese factory, and he is full of expectations and confidence in the future cooperation between the two sides.

Shortly after his return to Honduras, Mr. Rodriguez placed a large order with a total value of $200,000 covering the core product line of the Xin Oasis factory. Xin Oasis has been identified as a major supplier for his factory and plans to further expand its purchases in the future, he said.

This decision by Mr. Rodriguez fully demonstrates the high level of trust and recognition of the Xin Oasis factory.